These big systems, with lots of wires, electronics and mechanics, seem daunting at first but it’s complexity is divided into smaller sub-components that each have a particular task within the entire system. For this repeair, we first focus on getting the power back to the sub-systems, which means we focus on the power supply. After we fix this, we’ll have the opportunity to focus on the next sub-systems.

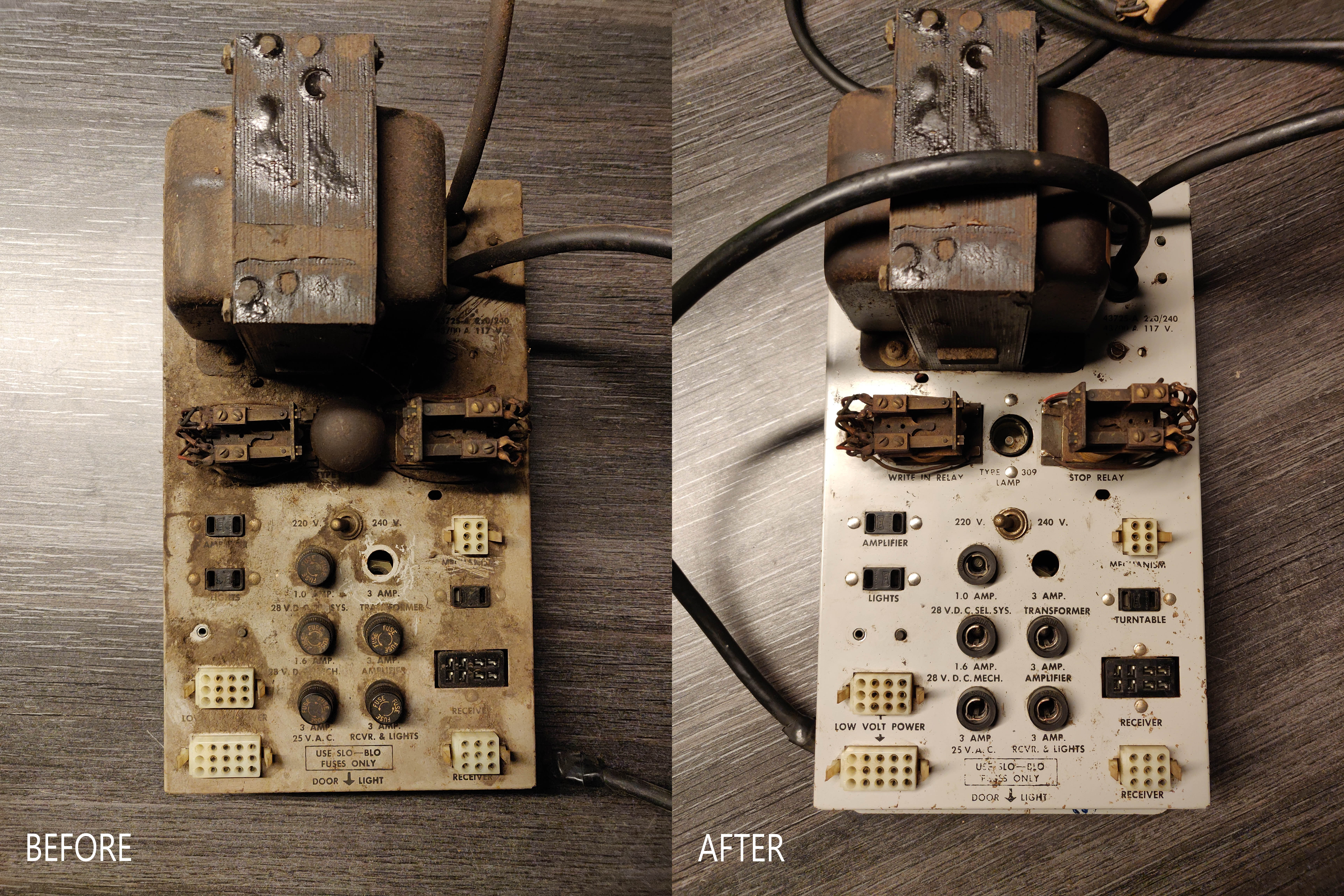

Simply by looking at the power supply portion of the jukebox, it starts to show to what lengths Rock-Ola went to make this servicable. The entire power supply can be simply removed from the cabinet by undoing two wing nuts on the front of the module. Any oriented connector was keyed in order to ensure being correctly plugged in. Additionally they made sure the connector size differs per cable so it always ends up in the correct socket.

Though not really necessary, all cables were tagged and documented in order to ensure they end up in the right place. The power supply was cleaned and the current limiting lamp, where the glass bulb had come loose from its socket, carefully removed. This current limiting lamp acts is part of the carousel motor circuitry which we’ll get back to in a later post.

Additionally one of the main fuse holders was replaced becaus the bakelite chassis broke off. The plastic replacement had a larger mounting diameter so the hole was increased with a rounded metal file.

With the power back available to the system, it was time to focus on the next task.

Let There Be Light!

These jukeboxes are made in the US and thus run internally on 110-120V AC. Due to the use of 110V lighting ballast and American sized fluorescent lights, repairs are often quite expensive.

There are two schools of thought in Europe with regards how to revise Jukebox lighting:

- Keep it US: just accept the high price of 110V ballasts and lighting and fix it, but remain close to original.

- Make it European: Wire the entire lighting off the primary 220V winding and use European ballasts and the more prevalent T8 with European sizes, thus reducing the cost of repair at the expense of deviating from the original.

We chose to “keep it US” as at the time most of the complexity of the jukebox was still unknown to me and there was no point in needlessly increasing its complexity even further.

The original lights had a F25T12-CW designation, meaning 25 watts and a diameter of 12/8ths of an inch and Cool White (4000K) color temperature. T12’s are no common size and their 30 and 33 inch versions are near impossible to find unless you go specialized jukebox repair sites. Replacing the lights and the starters did resolve all lighting issues and for the first time since long, the jukebox showed signs of life.

With the power supply and the lighting sorted, we can go one step deeper into the system and have a look at why the record grabbing mechanisms is not working.